In recent years, there has been a growing interest in sustainable and eco-friendly alternatives across various industries. The textile industry is no exception, and one promising solution gaining momentum is hemp fiber. Hemp, a versatile and fast-growing plant, has become a focal point for sustainable textile production. The key to unlocking its potential lies in advanced hemp fiber extraction machines.

The Rise of Hemp Fiber

Hemp has been cultivated for centuries, but its use in textiles has been limited due to the challenges in separating the fibers from the plant's stalks. Traditional methods often involve manual labor and can be time-consuming. However, with technological advancements, hemp fiber extraction machines have emerged as game-changers in streamlining the process.

How Hemp Fiber Extraction Machines Work

Hemp fiber extraction machines employ a combination of mechanical and automated processes to extract high-quality fibers from hemp stalks. The basic steps include:

Harvesting: Hemp plants are cultivated and harvested, usually after reaching peak maturity.

Retting: This is a crucial step where the hemp stalks undergo a natural process of decomposition to break down the binding agents that hold the fibers together. Traditional retting methods involve water, but modern machines may use advanced techniques to expedite the process.

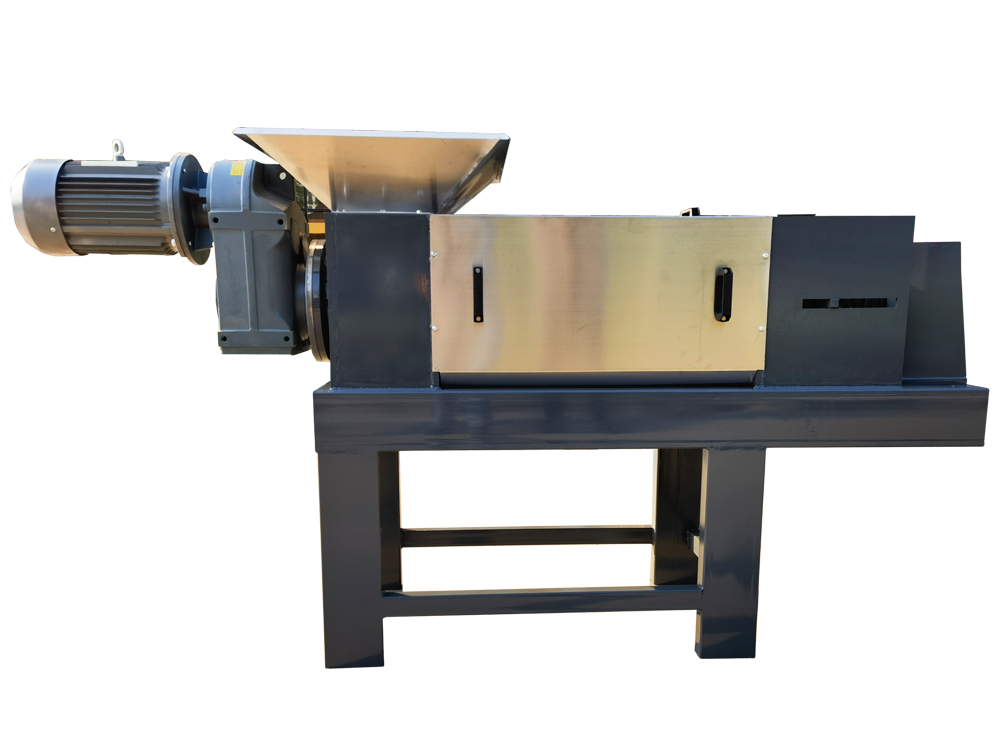

Decortication: The retted hemp stalks are fed into decortication machines. These machines use mechanical methods to separate the outer bast fibers from the inner woody core (hurd). The result is a clean and pure hemp fiber ready for further processing.

Cleaning and Finishing: The extracted fibers undergo cleaning processes to remove impurities and achieve the desired level of purity. They may then undergo additional treatments to enhance their quality and characteristics.

Advantages of Hemp Fiber Extraction Machines

Efficiency: Hemp fiber extraction machines significantly reduce the time and labor required for fiber separation compared to traditional methods.

Quality: The mechanical processes ensure a higher degree of consistency and purity in the extracted fibers, leading to high-quality end products.

Sustainability: Hemp is known for its sustainability, requiring minimal water and no pesticides. Hemp fiber extraction machines further contribute to the overall eco-friendliness of the process.

Versatility: The extracted hemp fibers can be used for a wide range of textile applications, including clothing, upholstery, and industrial textiles.

The Future of Sustainable Textiles

As the demand for sustainable textiles continues to rise, hemp fiber extraction machines are at the forefront of transforming the textile industry. Their ability to efficiently extract high-quality fibers from hemp not only meets the growing demand for eco-friendly materials but also opens doors for innovation in various sectors.

In conclusion, hemp fiber extraction machines play a pivotal role in unlocking the potential of hemp as a sustainable and versatile textile resource. With ongoing advancements in technology, these machines are likely to further streamline the process, making hemp a mainstream choice for environmentally conscious industries. The future of textiles is green, and hemp is leading the way.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China